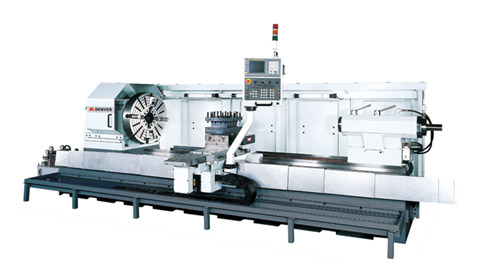

5 guide way / Spindle bore : 9", 10",12", 15", 20" / Bed width: 49"

Strong, stable ,smooth, and efficient processing advantages.

SPINDLE BORE: 9", 10",12", 15", 20"

-only fit to swing over bed over 1120mm

Photo shown : RHL-1120 X 4000

(with optional full splash guard, optional hydraulic tailstock. )

*Standard accessories shall be subject to the quotation.

Main Feature:

R&D Innovation Structural Multi Guide Way

The Bed is designed with 5 guide ways .

The design of leadscrew set in the middle let the effect of saddle movement to be more smoother.

Special design for apron support guide way to provide larger cutting capacity with heavier load.

Lathe over 4 meter will be mounted an extra linear way to strength the support capacity,

increase the processing accuracy, and reduce the abrasion of ball screws.

- 1. Once completed processing procedures

- This lathe is designed with multiple guideways. Because tailstock or steady rest are fixed on the 4th, 5th guideways and saddle slides on the 2nd, 3rd guideways while processing, it overcome completely the interference between saddle, tailstock and steady rest. Let saddle and tool turret complete smoothly the turning & processing procedure, operate easily and conveniently. (See fig.1))

- 2. The smooth internal drive

- Saddle, the bracket of ball screw and ball screw are mounted between the 2nd and 3rd guideway to correspond with each other. This distributes stress dispersed between the saddle and 2nd, 3rd guideways evenly when ball screw drives the saddle, enable ball screw drive the saddle more smoothly.

- 3. Cutting large diameter, more stable, more precision

- The saddle and tool rest travel along the 2nd and 3rd guideway, which is different from general configuration that suspended the cutting tool rest outside the 2nd guideway. This unique design increases higher of stability and precision while large diameter of workpiece.

- 4. Increase the cutting speed and stability of sliding

- While processing, even the cutting tool rest is shifted to the top or outside of the 2nd guideway, the equipment of the saddle and tool rest traveling along the 2nd and the 3rd guideway provide support to absorb the torsion caused from cutting work on the saddle & tool rest. This innovation gives outstanding stability and the accuracy.

- 5. Box-Bottom Bed Design

- High - rigidity body structure, the main structures of all aircraft used high MEEHANITE material. One piece casting. Box at the bottom of the design and strengthen their internal structure, raise the cutting strength of large workpiece.

- 6. Auto. lubrication system

- Auto lubrication system is controlled by PLC; oil will feed fixed volume for X / Z-axes during operating. There are two judging ways for feeding oils during operation. It will judge to feed oils automatically when cutting to a fixed length or machine's running to a fixed time.

|

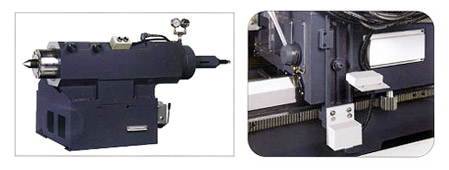

7. Tailstock Self-Rotary quill, when the main spindle turns, the tailstock's quill turns simultaneously (synchrony) with the main spindle, which lightens the load while raising stability. Mounted with taper roller bearings can bear heavy duty cutting. The quill is hardened and precision ground, adopted worm gear type design for quill's extending and retracting matched with gear motor, that is controlled easily and has the effect of anti-retract function on quill. The main body of tailstock matched with gear motor can move smoothly. The base of tailstock matched with rack equipment has an effect to prevent the tailstock body from retraction. |

|

- 1. Spindle bore : 9", 10",12", 15", 20"

- 2. Spindle motor: 30 ~ 100kw

- 3. Controller: SIEMENS

- 4. Transformer

- 5-1. 3-jaw chuck 20" , 25"

- 5-2. 3-jaw air chuck

- 5-3. Hydraulic 3-jaw wedge type through -hole power chuck 18"

- 5-4. Hydraulic 3-jaw wedge type non through -hole power chuck 18"

- 5-5. 4-jaw independent chuck 32", 40" ,50"

- 5-6. Face plate with 4-jaw 32", 40" ,50"

- 6-1. Steady rest 16" (O type or C type)

- 6-2. Steady rest 24" (O type or C type)

- 6-3. Hydraulic steady rest 16"

- 7. Follow rest

- 8-1. Hydraulic 4-way turret H4

- 8-2. Hydraulic turret V-12

- 8-3. Hydraulic 4-way turret H4-VDI

- 8-4. Power turret

- 9. Full splash guard

- 10. Spindle oil cooler

- 11. Boring attachment

- 12. 2-axes linear scale

- 13. Tailstock with quill dia. 200mm

- 14. Hydraulic quill

- 15. Tailstock base with hydraulic clamping system

- 16. Program tailstock

- 17. Double chuck device

- 18. Double turret

- 19. Grinder

- 20. Tailstock with 3-jaw chuck 12"

- 1. Controller: FANUC

- 2. Spindle 4-steps hydraulic auto speed

- 3. XZ-axes auto. lubrication system

- 4. XZ-axes with turcite-B

- 5. XZ-axes C3 ball screw

- 6. Rear chain type chip conveyor

- 7. Manual / electric tailstock

- 8. Steady rest 16"

- 9. Coolant system

- 10. Semi- back splash guard

- 11. Heat exchanger

- 12. Dead center

- 13. Level pads

- 14. Tools & tool box

- 15. Operational manual

- - This model can not enter the center, it can not come to center zero point

- - RHL is special designed only for the processing demand of mandrels, rollers, shafts and other same types of workpieces.

- ※ SPINDLE BORE: 9", 10",12", 15", 20" only fit to swing over bed over 1120mm.

Unit: mm / inch

| Model | RHL-960 | RHL-1120 | ||||

| Capacity | Max. Swing over Bed | 960 (37.78") | 1120 (44.09") | |||

| Center-Center | 2000 (78.74") 3000 (118.11") 4000 (157.48") 5000 (196.85") | |||||

| Max. Roll Cutting Dia. | 800 (31.5") | 1000 (39.37") | ||||

| Min. Roll Cutting Dia. | 63 (2.48") | 100 (4") | ||||

| Max. Cutting Length | 2000 (78.74") 3000 (118.11") 4000 (157.48") 5000 (196.85") | |||||

| Bed Way | 5 Guide Way | |||||

| Bed | Width of Bed | 1250 (49.21") | ||||

| Length of Bed | 4000 (157.48") 5000 (196.85") 6000 (236") 7000 (275.59") | |||||

| Headstock | Spindle bore diameter | ø152(6") | OP:ø230(9") | OP:ø255(10") | OP:ø312(12") | OP:ø380(15") |

| Spindle nose | A2-11 OP: A2-15 |

A2-15 OP: A2-20 |

A2-15 OP: A2-20 |

A2-20 | A2-20 | |

| Range of spindle speed | 6-500 rpm | 7-350 rpm | ||||

| 1. Range speed | 6-35 rpm | 7-20 rpm | ||||

| 2. Range speed | 19-112 rpm | 19-60 rpm | ||||

| 3. Range speed | 70-350 rpm | 40-121 rpm | ||||

| 4. Range speed | 226-500 rpm | 11-350 rpm | ||||

| * Spindle speed changed by different horse power. | ||||||

| No. of spindle speed | Auto 4 Steps / Hydraulic | |||||

| Travel | X-axis travel | 400 (15.75") ( by Hydraulic turret H4 ) | ||||

| * X-axis travel changed by different turret. | ||||||

| Z-axis travel | 2000 (78.74") 3000 (118.11") 4000 (157.48") 5000 (196.85) | |||||

| * Z-axis travel changed by different turret , chuck or tailstock. | ||||||

| Dia. of X-axis ball screw | 40 mm, pitch 10 mm | |||||

| Dia. of Z-axis ball screw | 63 mm, pitch 10 mm | |||||

| TURRET | Turret type | Hydraulic turret H4 , V12, H4-VDI | ||||

| Tool shank / Numbers | 32 x 32 (1.23" x 1.23") (OP: 40 x 40 (1.57" x 1.57") ) | |||||

| Tailstock | Quill Dia. | 150 (5.9") (OP: 200 (7.87")) | ||||

| Quill travel | 300 (11.81") | |||||

| Quill taper | MT6 | |||||

| Quill movement | Manual / electric (OP: Hydraulic) | |||||

| Body movement | Electric (OP: Hydraulic) | |||||

| Lock-type | Manual ( OP:Hydraulic) (option) | |||||

| Motor | Spindle Motor | Continuous / 30min rating 22/26 KW – for 2000~3000 ( OP:30-100 KW) 30/37 KW – for 4000~5000 ( OP:37-100KW) |

||||

| X-axis servo Motor | 4 kw | |||||

| Z-axis servo Motor | 4 kw | |||||

| Tailstock body drive Motor | 0.4 kw | |||||

| Tailstock quill drive Motor | 0.2 kw | |||||

| Hydraulic pump | ( 1.5kw ) (2HP) | |||||

| Coolant pump | 1.275 kw (1.7HP) | |||||

| Measurement | Machine size | L: 4250 (167.3")5250 (206.7")6250 (246.1")7250 (285.4") x W:2500 (98") xH:2260 (89") |

||||

| Floor space | L: 6650 (261.8")7650 (301.2") 8650 (340.6") 9650 (379.9") x W: 3820 (150.4") | |||||

| N.W. / G.W. (approx)-960 (kgs) | 15500/16400, 17500/18500, 19500/20600, 21500/22700 | |||||

| N.W. / G.W. (approx)-1120 (kgs) | 16000/16900, 18000/19000, 20000/21100,22000/23200 | |||||

| Packing size for semi back splash guard (by 40' HQ container) | L: 6600 (259.8")7600 (229.2)8600 (338.6")9600 (378") x W: 2300 (150.4") xH2400 (94.5") | |||||

| Color | Upper parts: RAL-7035 (Light gray) + Base: RAL-7024 (Dark gray) |

|||||